Manufacturing

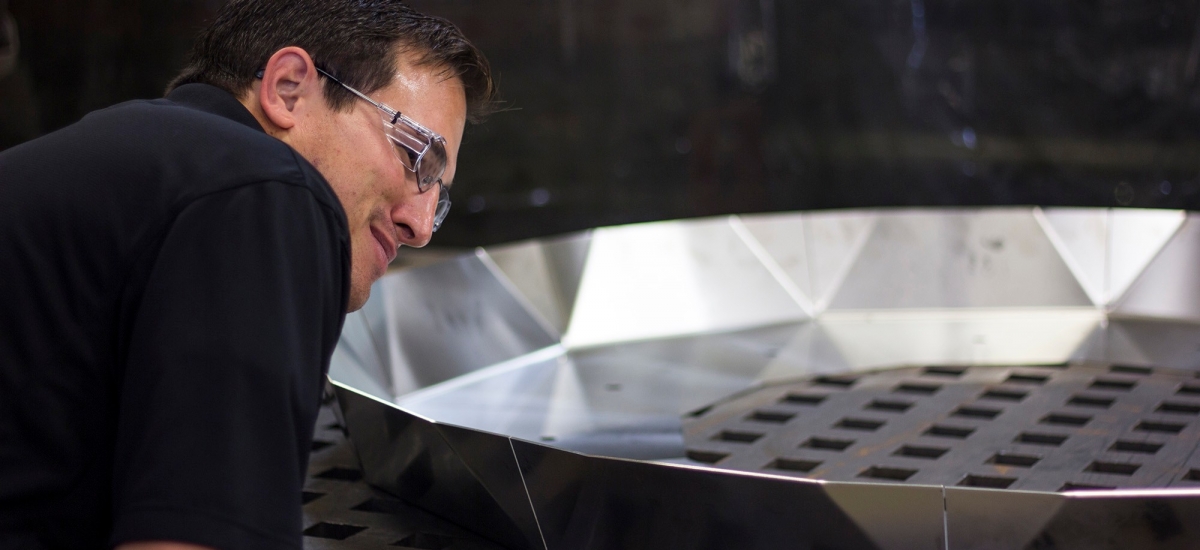

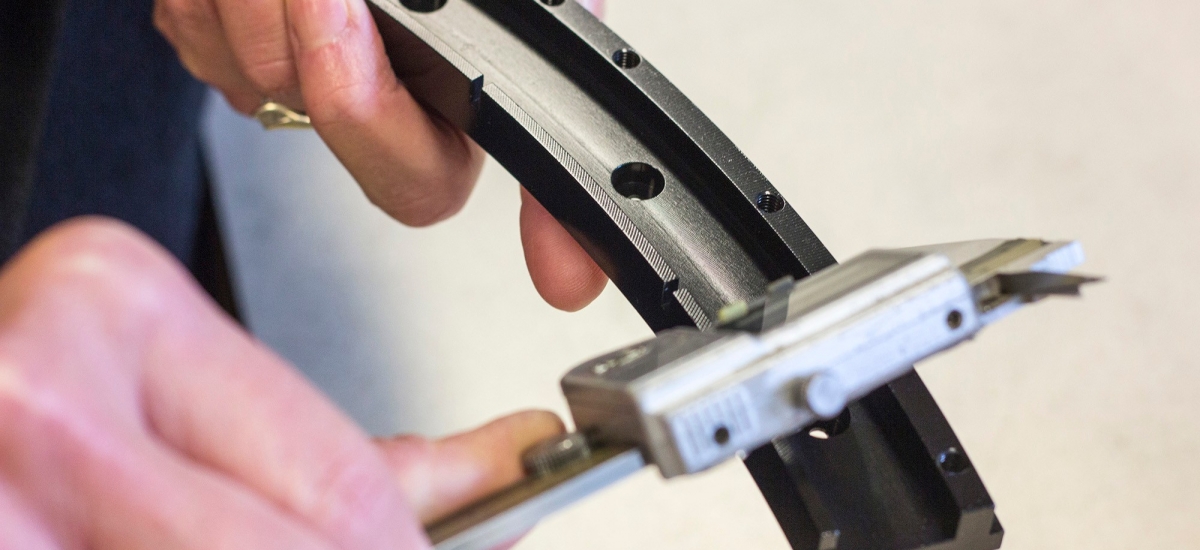

Machining and Fabrication

Our team includes CNC Programmers, machinists, operators, and welders who collaborate with our customers to provide quick turn-around of prototype parts, precision fixtures and production components. We are committed to delivering prototype parts as quickly as possible. As we all know, the more complex the part, the longer it takes to make, so we also offer consultation services to make your parts easier to manufacture.

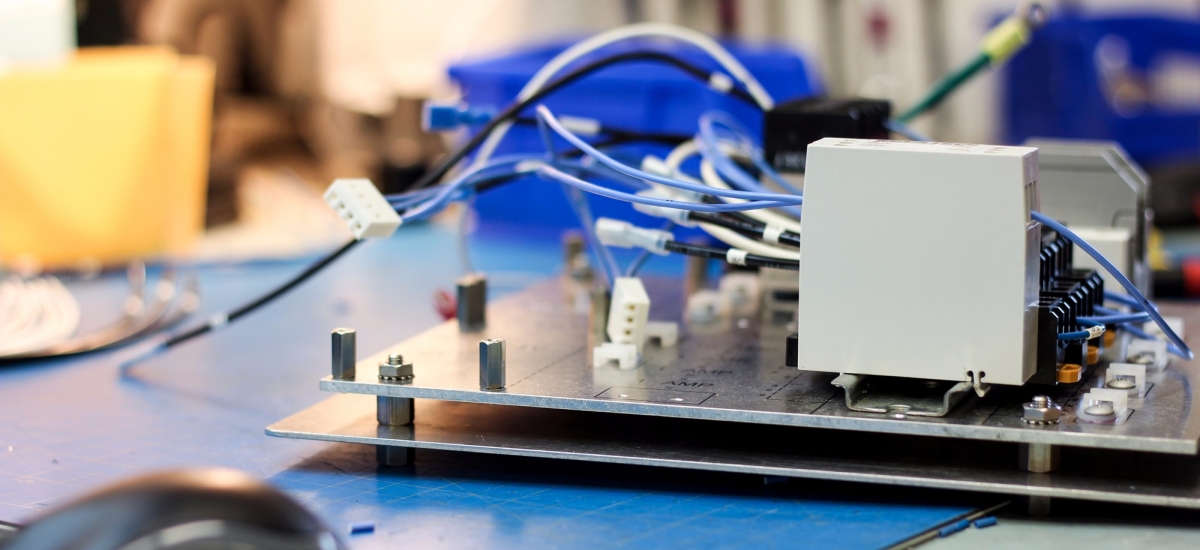

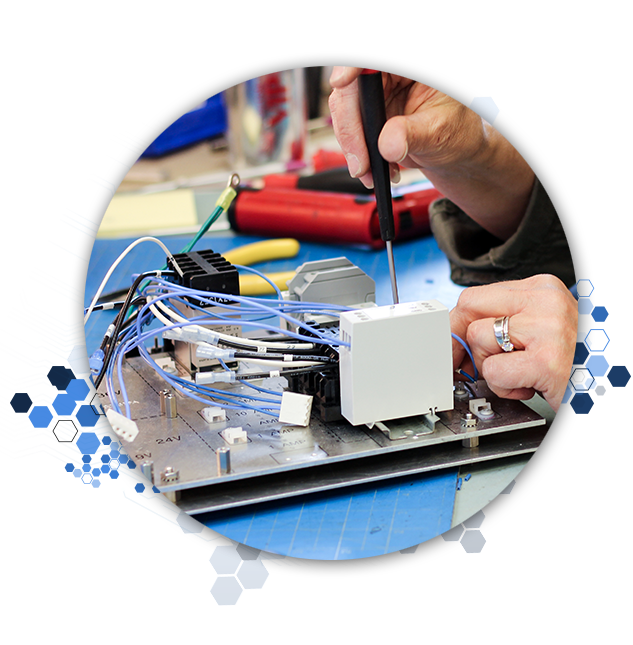

Assembly

Our team includes Assembly Technicians, QC Test Technicians and Final Assembly & Test Technicians. Committed to continuous improvement, all assemblies are created with detailed work instructions and are tested to ensure electrical and mechanical functionality before delivery.

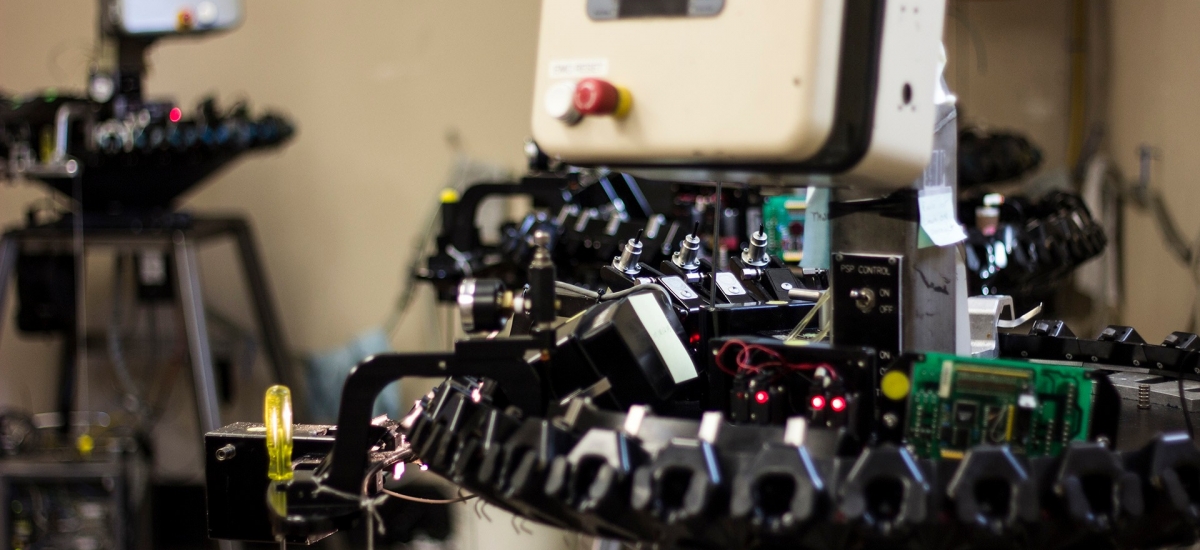

Refurbishing

Our Refurbishing team includes a Receiving Group, focused on disassembly, decontamination and restoration of components, and a Repair Group, focused on troubleshooting and re-manufacturing. Cost savings through refurbishing range from 50-90% of new. We maintain a supply of parts and modules that allow us to ship to our customers on a moment’s notice. We offer reliability analysis data that can drive design improvements leading to longer life and even lower life cycle costs.

Production Support

Our team includes Manufacturing Engineering, ERP support, Procurement and Technical Writing. We improve efficiency, cut out waste and streamline all manufacturing processes and systems. Collaboration with the manufacturing teams and development engineering is key to our success.

Inventory

Our team provides accurate counts and locations for all materials in manufacturing and leased equipment worldwide. Nearly all Nova-Tech parts flow through the Inventory Team. We fill parts requests for Engineering, accelerating product development.

Quality

Our focus is on achieving continuous improvement goals. We offer tools and systems so our internal customers know that what they create meets or exceeds specifications. We provide data-driven analysis of the entire quality stream.